Đùn nhôm tùy chỉnh

High-Quality Custom Extrusions From China: The First Choice For Personalized Applications

In many applications, standard extruded aluminum profiles, while functional, are not always suitable for specific project needs. Sometimes, your project may have unique attributes that require a more personalized solution. We offer custom molding services to complete aluminum profiles according to your preferences and needs. Additionally, we can perform any other manufacturing operations you require. We are aluminum profiles manufacturer that has passed ISO9001 quality system certification. We will open up a world of possibilities for you and ensure the smooth implementation of your project.

Minimum order quantity (MOQ): 500 kg per shape

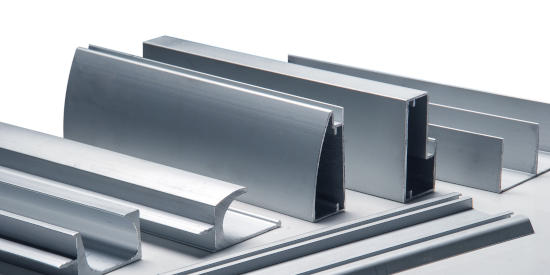

Custom Extruded Shapes

When your project requires custom aluminum extrusion shapes, you can count on our team of professionals to have your back. We offer various types of custom shapes including hollow, semi-hollow and solid aluminum profiles. Ruiyu Aluminum has several extruders with an extrusion force of 600-4000 tons and a self-operated mold factory, using H13 steel molds to ensure the smooth start of your project. With our custom extruded shape services, you'll find the perfect solution for your project needs.

Industrial Aluminum Alloys

6061 and 6063 aluminum alloys have advantages in the industrial field. They offer excellent strength, toughness, corrosion resistance and processability along with a high surface finish, making them suitable for a variety of industrial applications.

The Manufacturing Options You Need

Depending on your aluminum extrusion needs, we offer a variety of secondary processing options. This includes machining, surface treatment, drilling, stamping and cutting to specific lengths. In addition, we offer surface treatment services,such as Powder Coating, Anodizing, and Wood grain finishes, etc.

Custom Extrusion: What is the Process?

Custom extrusion is a highly flexible manufacturing process that can be used to produce aluminum profiles in a variety of shapes and sizes. This process involves multiple steps, from designing the mold to the final finished product. Let’s take a closer look at the various stages of this process.

First, our engineers will design a custom mold based on your drawings. Next, your chosen aluminum alloy is loaded onto the extruder and forced into this custom mold via a powerful plunger. The high temperature inside the extruder gives the aluminum alloy good fluidity and plasticity.

As the aluminum alloy passes through the mold, it assumes the desired shape. The profile is then mechanically stretched during cooling and sawed to the specified length. This process is usually air or water cooled to ensure that the profile maintains its shape and dimensional stability.

After initial machining, the aluminum extrusion profile needs to be further cooled and then mechanically stretched to ensure that its internal stresses are relieved and aligned. After this stage, the aluminum extrusion profiles is heat treated to improve its mechanical properties and corrosion resistance.

Finally, in the final stage of the custom extrusion process, various manufacturing operations such as machining, surface treatment, etc. can be performed according to your needs. These operations will further enhance the performance and appearance of the aluminum extrusion profile, making it ideal for a variety of applications.

Alloys, Temper & Secondary Services for Custom Extrusions:A One-Stop Solution

| Attribute | Options Avaliable |

| Alloys | 1050,1070,1350,2014,3003,3103,5052,50545083,5086,6060,6061,6063,6005,6026 ,6066,6082,6101,6106,6261,6262,6351 |

| Tempers | M, O, T4, T5, T52,T6,T66,T6511 |

| FinishingServices | Sandblasting, Anodizing, PowderCoating, Sublimation (Wood Look) |

| OtherSecondary | Machining, Cutting, Stamping, Drilling, Welding,Assemblies, etc. |

| Profile Width | Up to 400mm depending on shape, size, and CCD |

Our extruders offer a range of alloying, tempering, finishing and other ancillary services. With our one-stop solution, you can easily find the perfect aluminum extrusion for your project requirements. This table provides some key information about our products.

We understand that every aluminum profile application project has its own unique needs and challenges. Therefore, we continuously optimize our aluminum profiles production processes and technologies to ensure that you receive the highest quality products and services.

Custom Extrusions for Your Industry and Application

As a versatile manufacturing process, aluminum extrusion has been widely used in many industries and application scenarios. From construction to electronics to automotive, we help our customers produce the aluminum extrusion they need to ensure full compliance with specifications.

Custom aluminum extrusions can meet specific performance, size and appearance needs, providing significant advantages to a variety of industries. In the construction field, aluminum extrusions can be used in door and window frames, partitions and support structures; in the electronics industry, they are used in radiators, housings and guide rails; and in the automotive field, aluminum extrusions are used in lightweight components , suspension system and body structure, etc.

Architectural

Electronics

Automotive

Aerospace

Solar Panels

Transportation

Automation

Medical